-

111,South Yutian Road

Shanghai,China

-

Opening Time

Mon - Sat: 09.00 to 18.00

-

Mail Us

[email protected]

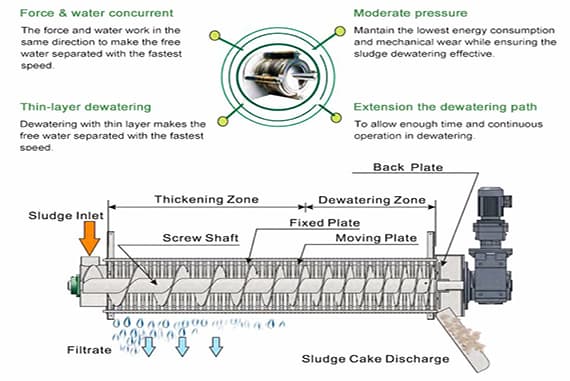

The main part of the dehydrator is a filter device that a screw runs through the stacked fixed rings and moving ring.

The small gaps between fixed rings and moving ring can filter the sludge, and the lumen between screw and rings is filled with polymer grains. The moving ring transfers the sludge to the end of the machine with pressure and extrudes sludge cakes.

Layers of the spacers, which are Fixed and Moving Rings, are secured in place by a tie rod. The inner diameters of the Moving Rings are slightly smaller than the outer diameter of the screw and their rings. Mobilized by the screw, it continuously cleans the sludge out of the gaps, therefore, preventing clogging.

The running of the screw drives the moving ring to clean the gaps and avoid jam.

1. Force-water cocurrentForce and water are in the same direction, making the free water comes out at the fastest speed. 2. Extension of deatering pathNot only ensuring the amount of time during the process of sludge dewatering, but also ensuring the continuous operation. 3. Moderate pressureMaintain lowest energy consumption and mechanical wear while ensuring the sludge dewatering effect. 4. Thin-layer dewatering Thinning the sludge to make the free water come out by going a shorest distance.

|

MD SLUDGE DEWATERING PRESS SPECIFICATION

| Model | Dried Sludge Standard Capacity(kg/h) |

Sludge Treatment Capacity(m³/h) |

||||||

Low Concentration |

High Concentration |

2000mg/L |

4000mg/L |

10000mg/L |

20000mg/L |

25000mg/L |

50000mg/L |

|

| MD131 | ~ 6 | ~ 12 | ~ 3 | ~ 1.5 | ~ 1.2 | ~ 0.6 | ~ 0.48 | ~ 0.24 |

| MD132 | ~ 12 | ~ 24 | ~ 6 | ~ 3 | ~ 2.4 | ~ 1.2 | ~ 0.96 | ~ 0.48 |

| MD201 | ~ 12 | ~ 20 | ~ 6 | ~ 3 | ~ 2 | ~ 1 | ~ 0.8 | ~ 0.4 |

| MD202 | ~ 24 | ~ 40 | ~ 12 | ~ 6 | ~ 4 | ~ 2 | ~ 1.6 | ~ 0.8 |

| MD 311 | ~ 30 | ~ 60 | ~ 15 | ~ 7.5 | ~6 | ~ 3 | ~ 2.4 | ~ 1.2 |

| MD312 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD 313 | ~ 90 | ~ 180 | ~ 45 | ~ 22.5 | ~ 18 | ~ 9 | ~ 7.2 | ~ 3.6 |

| MD314 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD411 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD412 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~ 24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD413 | ~ 180 | ~ 360 | ~ 90 | ~ 45 | ~ 36 | ~ 18 | ~ 14.4 | ~ 7.2 |

| MD414 | ~ 240 | ~ 480 | ~ 120 | ~ 60 | ~ 48 | ~24 | ~ 19.2 | ~ 9.6 |

| MD511 | ~90 | ~ 150 | ~ 45 | ~ 22.5 | ~15 | ~7.5 | ~ 6 | ~ 3.5 |

| MD512 | ~ 180 | ~ 300 | ~ 90 | ~ 45 | ~30 | ~15 | ~12 | ~ 7 |

| MD513 | ~ 270 | ~ 450 | ~ 135 | ~ 67.5 | ~45 | ~22.5 | ~ 18 | ~ 10.5 |

| MD514 | ~ 360 | ~ 600 | ~ 180 | ~ 90 | ~60 | ~30 | ~ 24 | ~ 14 |

① Use three letters and three digits to represent the Model.

The letter MD means machine type—Multi-Disk Screw. Two former digits means the MD cylinder diameter, the last digit shows the number of the screw shafts, such as MD312,it means the MD cylinder diameter is 310mm, the number of the screw shafts is two.

② Sludge Treatment Capacity=DS Standard Capacity÷Sludge Concentration (DS stands for Dried Sludge, 0% moisture.

* Throughput of each model is based on sludge cake with 85% water content.

* There is no certain upper limitation on inlet sludge concentration, however, the target sludge must be flowable.

* Throughput of DAF Sludge is based on sludge containing much fat, oil, and grease such as meat processing applications etc.

* Throughput of Mixed Sludge (Primary Sludge and Waste Activated Sludge) and Aerobically Digested Sludge is based on sludge containing more than 30% fiber (200 mesh) against Total Solids.