-

111,South Yutian Road

Shanghai,China

-

Opening Time

Mon - Sat: 09.00 to 18.00

-

Mail Us

[email protected]

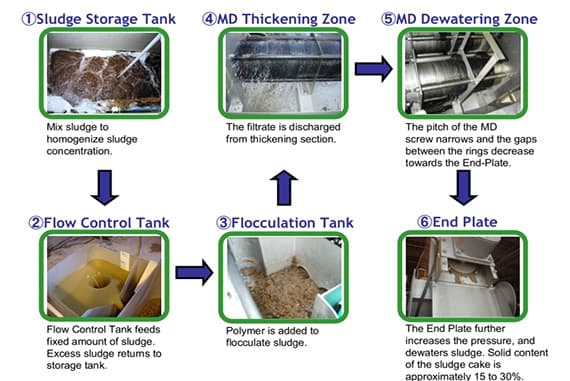

TThe sludge thickener thickens sludge with concentration of 1% or less to that with a concentration of 4 to 6%. This mechanical thickening will constantly produce stable thickened sludge, which is difficult with gravity thickening. It is possible to install as pre-thickener for your existing belt press or centrifuge to improve their dewatering performance. Furthermore, even in some facilities where the dewatered cakes are not easily transported, the volume of sludge to be disposed of can be reduced by thickening and yet it is still easily transported (pumped) as it is still in liquid form.

It has solved several technical problems of other similar sludge dewatering equipment including belt presses, centrifuge machines, plate-and-frame filter press have, which are frequent clogging, low concentration sludge / oil sludge treatment failure, high energy consumption and complicated operation etc.

MD SLUDGE DEWATERING MACHINE SPECIFICATION

| Model | Dried Sludge Standard Capacity(kg/h) |

Sludge Treatment Capacity(m³/h) |

||||||

Low Concentration |

High Concentration |

2000mg/L |

4000mg/L |

10000mg/L |

20000mg/L |

25000mg/L |

50000mg/L |

|

| MD131 | ~ 6 | ~ 12 | ~ 3 | ~ 1.5 | ~ 1.2 | ~ 0.6 | ~ 0.48 | ~ 0.24 |

| MD132 | ~ 12 | ~ 24 | ~ 6 | ~ 3 | ~ 2.4 | ~ 1.2 | ~ 0.96 | ~ 0.48 |

| MD201 | ~ 12 | ~ 20 | ~ 6 | ~ 3 | ~ 2 | ~ 1 | ~ 0.8 | ~ 0.4 |

| MD202 | ~ 24 | ~ 40 | ~ 12 | ~ 6 | ~ 4 | ~ 2 | ~ 1.6 | ~ 0.8 |

| MD 311 | ~ 30 | ~ 60 | ~ 15 | ~ 7.5 | ~6 | ~ 3 | ~ 2.4 | ~ 1.2 |

| MD312 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD 313 | ~ 90 | ~ 180 | ~ 45 | ~ 22.5 | ~ 18 | ~ 9 | ~ 7.2 | ~ 3.6 |

| MD314 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD411 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD412 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~ 24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD413 | ~ 180 | ~ 360 | ~ 90 | ~ 45 | ~ 36 | ~ 18 | ~ 14.4 | ~ 7.2 |

| MD414 | ~ 240 | ~ 480 | ~ 120 | ~ 60 | ~ 48 | ~24 | ~ 19.2 | ~ 9.6 |

| MD511 | ~90 | ~ 150 | ~ 45 | ~ 22.5 | ~15 | ~7.5 | ~ 6 | ~ 3.5 |

| MD512 | ~ 180 | ~ 300 | ~ 90 | ~ 45 | ~30 | ~15 | ~12 | ~ 7 |

| MD513 | ~ 270 | ~ 450 | ~ 135 | ~ 67.5 | ~45 | ~22.5 | ~ 18 | ~ 10.5 |

| MD514 | ~ 360 | ~ 600 | ~ 180 | ~ 90 | ~60 | ~30 | ~ 24 | ~ 14 |

① Use three letters and three digits to represent the Model.

The letter MD means machine type—Multi-Disk Screw. Two former digits means the MD cylinder diameter, the last digit shows the number of the screw shafts, such as MD312,it means the MD cylinder diameter is 310mm, the number of the screw shafts is two.

② Sludge Treatment Capacity=DS Standard Capacity÷Sludge Concentration (DS stands for Dried Sludge, 0% moisture.

* Throughput of each model is based on sludge cake with 85% water content.

* There is no certain upper limitation on inlet sludge concentration, however, the target sludge must be flowable.

* Throughput of DAF Sludge is based on sludge containing much fat, oil, and grease such as meat processing applications etc.

* Throughput of Mixed Sludge (Primary Sludge and Waste Activated Sludge) and Aerobically Digested Sludge is based on sludge containing more than 30% fiber (200 mesh) against Total Solids.