-

111,South Yutian Road

Shanghai,China

-

Opening Time

Mon - Sat: 09.00 to 18.00

-

Mail Us

[email protected]

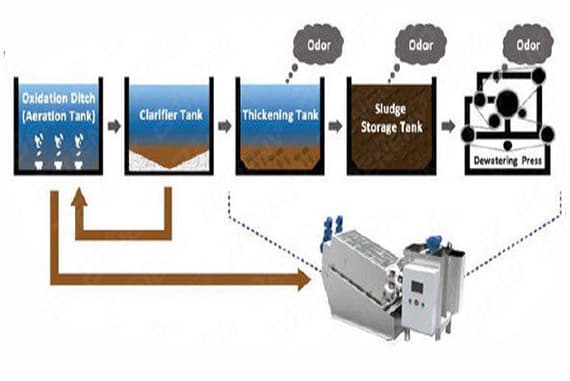

1. Sludge is firstly fed into the Flow Control Tank and then flows down into the Flocculation Tank, where polymer coagulant is added.

2. From there, the flocculated sludge overflows into the dewatering drum where it is filtered and compressed. The entire operation sequence, including sludge feed control, polymer makeup, dosing and sludge cake discharge are controlled by the built-in timer and sensors of the PLC.

The Sludge Dewatering Press offers a completely operational, skid mounted and self-contained system which can include:

• Screw Press • PLC Controls •Sludge Pumps •Back Wash System •Flocculation System •Polymer Dosing Unit •Sludge Cake Conveyor.

MD SLUDGE DEWATERING MACHINE SPECIFICATION

| Model | Dried Sludge Standard Capacity(kg/h) |

Sludge Treatment Capacity(m³/h) |

||||||

Low Concentration |

High Concentration |

2000mg/L |

4000mg/L |

10000mg/L |

20000mg/L |

25000mg/L |

50000mg/L |

|

| MD131 | ~ 6 | ~ 12 | ~ 3 | ~ 1.5 | ~ 1.2 | ~ 0.6 | ~ 0.48 | ~ 0.24 |

| MD132 | ~ 12 | ~ 24 | ~ 6 | ~ 3 | ~ 2.4 | ~ 1.2 | ~ 0.96 | ~ 0.48 |

| MD201 | ~ 12 | ~ 20 | ~ 6 | ~ 3 | ~ 2 | ~ 1 | ~ 0.8 | ~ 0.4 |

| MD202 | ~ 24 | ~ 40 | ~ 12 | ~ 6 | ~ 4 | ~ 2 | ~ 1.6 | ~ 0.8 |

| MD 311 | ~ 30 | ~ 60 | ~ 15 | ~ 7.5 | ~6 | ~ 3 | ~ 2.4 | ~ 1.2 |

| MD312 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD 313 | ~ 90 | ~ 180 | ~ 45 | ~ 22.5 | ~ 18 | ~ 9 | ~ 7.2 | ~ 3.6 |

| MD314 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD411 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD412 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~ 24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD413 | ~ 180 | ~ 360 | ~ 90 | ~ 45 | ~ 36 | ~ 18 | ~ 14.4 | ~ 7.2 |

| MD414 | ~ 240 | ~ 480 | ~ 120 | ~ 60 | ~ 48 | ~24 | ~ 19.2 | ~ 9.6 |

| MD511 | ~90 | ~ 150 | ~ 45 | ~ 22.5 | ~15 | ~7.5 | ~ 6 | ~ 3.5 |

| MD512 | ~ 180 | ~ 300 | ~ 90 | ~ 45 | ~30 | ~15 | ~12 | ~ 7 |

| MD513 | ~ 270 | ~ 450 | ~ 135 | ~ 67.5 | ~45 | ~22.5 | ~ 18 | ~ 10.5 |

| MD514 | ~ 360 | ~ 600 | ~ 180 | ~ 90 | ~60 | ~30 | ~ 24 | ~ 14 |

① Use three letters and three digits to represent the Model.

The letter MD means machine type—Multi-Disk Screw. Two former digits means the MD cylinder diameter, the last digit shows the number of the screw shafts, such as MD312,it means the MD cylinder diameter is 310mm, the number of the screw shafts is two.

② Sludge Treatment Capacity=DS Standard Capacity÷Sludge Concentration (DS stands for Dried Sludge, 0% moisture.

* Throughput of each model is based on sludge cake with 85% water content.

* There is no certain upper limitation on inlet sludge concentration, however, the target sludge must be flowable.

* Throughput of DAF Sludge is based on sludge containing much fat, oil, and grease such as meat processing applications etc.

* Throughput of Mixed Sludge (Primary Sludge and Waste Activated Sludge) and Aerobically Digested Sludge is based on sludge containing more than 30% fiber (200 mesh) against Total Solids.