-

111,South Yutian Road

Shanghai,China

-

Opening Time

Mon - Sat: 09.00 to 18.00

-

Mail Us

[email protected]

The dewatering body is formed by a screw axis with fixing and moving plates overlapping, as the inner diameter of screw axis is larger than the moving plate, it do the circular motion with the screw axis to prevent clogging, to ensure the continuous operation

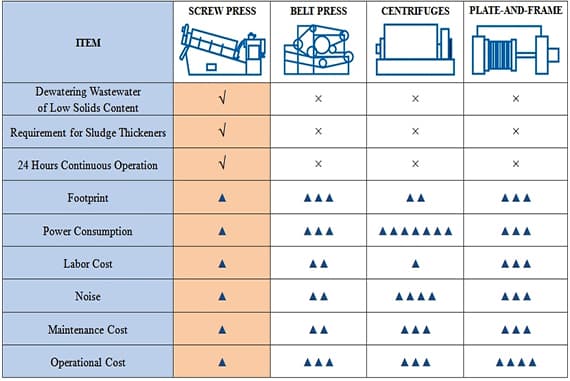

Comparing with the traditional belt, plate& frame and centrifugal machine,volute sludge dewatering machine adopts integrated design of dehydration ontology, flocculation mixing tank and electric control device, convenient installation , small area cover, strong compatibility with ancillary equipment, greatly reduce design and the construction cost, at the same time, no need to undertake civil construction as its exquisite design.

|

Can realise 24 hours automatic unmanned operation by PLC remote control , reduce the operating personnel employment and maintenance costs. At the same time, due to the exquisite design, easy operation, it is easy to learn as no special knowledge and skilled technical complex requirements. Main body can self-cleaning due to the special structure, threr is no need to use a lot of water for cleaning to prevent clogging. Compared with the same capacity of dewatering machine, screw rinse water consumption is only 1% of belt . The rotation speed of screw shaft is 2-5 turn/min , low power consumption. Power consumption is only 5% of the centrifuge, at the same time, no noise during operation as slow rotation speed and intermittent flush.

|

MD SLUDGE DEWATERING MACHINE SPECIFICATION

| Model | Dried Sludge Standard Capacity(kg/h) |

Sludge Treatment Capacity(m³/h) |

||||||

Low Concentration |

High Concentration |

2000mg/L |

4000mg/L |

10000mg/L |

20000mg/L |

25000mg/L |

50000mg/L |

|

| MD131 | ~ 6 | ~ 12 | ~ 3 | ~ 1.5 | ~ 1.2 | ~ 0.6 | ~ 0.48 | ~ 0.24 |

| MD132 | ~ 12 | ~ 24 | ~ 6 | ~ 3 | ~ 2.4 | ~ 1.2 | ~ 0.96 | ~ 0.48 |

| MD201 | ~ 12 | ~ 20 | ~ 6 | ~ 3 | ~ 2 | ~ 1 | ~ 0.8 | ~ 0.4 |

| MD202 | ~ 24 | ~ 40 | ~ 12 | ~ 6 | ~ 4 | ~ 2 | ~ 1.6 | ~ 0.8 |

| MD 311 | ~ 30 | ~ 60 | ~ 15 | ~ 7.5 | ~6 | ~ 3 | ~ 2.4 | ~ 1.2 |

| MD312 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD 313 | ~ 90 | ~ 180 | ~ 45 | ~ 22.5 | ~ 18 | ~ 9 | ~ 7.2 | ~ 3.6 |

| MD314 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD411 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD412 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~ 24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD413 | ~ 180 | ~ 360 | ~ 90 | ~ 45 | ~ 36 | ~ 18 | ~ 14.4 | ~ 7.2 |

| MD414 | ~ 240 | ~ 480 | ~ 120 | ~ 60 | ~ 48 | ~24 | ~ 19.2 | ~ 9.6 |

| MD511 | ~90 | ~ 150 | ~ 45 | ~ 22.5 | ~15 | ~7.5 | ~ 6 | ~ 3.5 |

| MD512 | ~ 180 | ~ 300 | ~ 90 | ~ 45 | ~30 | ~15 | ~12 | ~ 7 |

| MD513 | ~ 270 | ~ 450 | ~ 135 | ~ 67.5 | ~45 | ~22.5 | ~ 18 | ~ 10.5 |

| MD514 | ~ 360 | ~ 600 | ~ 180 | ~ 90 | ~60 | ~30 | ~ 24 | ~ 14 |

① Use three letters and three digits to represent the Model.

The letter MD means machine type—Multi-Disk Screw. Two former digits means the MD cylinder diameter, the last digit shows the number of the screw shafts, such as MD312,it means the MD cylinder diameter is 310mm, the number of the screw shafts is two.

② Sludge Treatment Capacity=DS Standard Capacity÷Sludge Concentration (DS stands for Dried Sludge, 0% moisture.

* Throughput of each model is based on sludge cake with 85% water content.

* There is no certain upper limitation on inlet sludge concentration, however, the target sludge must be flowable.

* Throughput of DAF Sludge is based on sludge containing much fat, oil, and grease such as meat processing applications etc.

* Throughput of Mixed Sludge (Primary Sludge and Waste Activated Sludge) and Aerobically Digested Sludge is based on sludge containing more than 30% fiber (200 mesh) against Total Solids.