-

111,South Yutian Road

Shanghai,China

-

Opening Time

Mon - Sat: 09.00 to 18.00

-

Mail Us

[email protected]

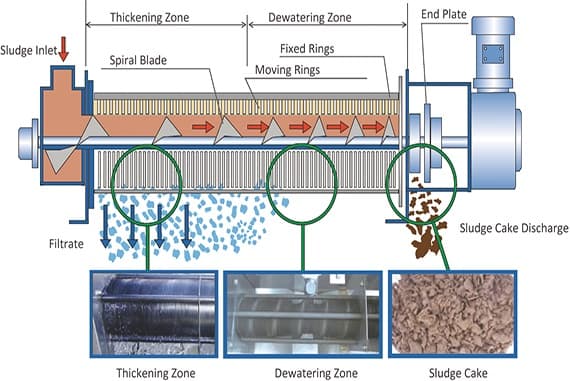

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity.

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

MD SLUDGE DEWATERING MACHINE SPECIFICATION

| Model | Dried Sludge Standard Capacity(kg/h) |

Sludge Treatment Capacity(m³/h) |

||||||

Low Concentration |

High Concentration |

2000mg/L |

4000mg/L |

10000mg/L |

20000mg/L |

25000mg/L |

50000mg/L |

|

| MD131 | ~ 6 | ~ 12 | ~ 3 | ~ 1.5 | ~ 1.2 | ~ 0.6 | ~ 0.48 | ~ 0.24 |

| MD132 | ~ 12 | ~ 24 | ~ 6 | ~ 3 | ~ 2.4 | ~ 1.2 | ~ 0.96 | ~ 0.48 |

| MD201 | ~ 12 | ~ 20 | ~ 6 | ~ 3 | ~ 2 | ~ 1 | ~ 0.8 | ~ 0.4 |

| MD202 | ~ 24 | ~ 40 | ~ 12 | ~ 6 | ~ 4 | ~ 2 | ~ 1.6 | ~ 0.8 |

| MD 311 | ~ 30 | ~ 60 | ~ 15 | ~ 7.5 | ~6 | ~ 3 | ~ 2.4 | ~ 1.2 |

| MD312 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD 313 | ~ 90 | ~ 180 | ~ 45 | ~ 22.5 | ~ 18 | ~ 9 | ~ 7.2 | ~ 3.6 |

| MD314 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD411 | ~ 60 | ~ 120 | ~ 30 | ~ 15 | ~ 12 | ~6 | ~ 4.8 | ~ 2.4 |

| MD412 | ~ 120 | ~ 240 | ~ 60 | ~ 30 | ~ 24 | ~ 12 | ~ 9.6 | ~ 4.8 |

| MD413 | ~ 180 | ~ 360 | ~ 90 | ~ 45 | ~ 36 | ~ 18 | ~ 14.4 | ~ 7.2 |

| MD414 | ~ 240 | ~ 480 | ~ 120 | ~ 60 | ~ 48 | ~24 | ~ 19.2 | ~ 9.6 |

| MD511 | ~90 | ~ 150 | ~ 45 | ~ 22.5 | ~15 | ~7.5 | ~ 6 | ~ 3.5 |

| MD512 | ~ 180 | ~ 300 | ~ 90 | ~ 45 | ~30 | ~15 | ~12 | ~ 7 |

| MD513 | ~ 270 | ~ 450 | ~ 135 | ~ 67.5 | ~45 | ~22.5 | ~ 18 | ~ 10.5 |

| MD514 | ~ 360 | ~ 600 | ~ 180 | ~ 90 | ~60 | ~30 | ~ 24 | ~ 14 |

① Use three letters and three digits to represent the Model.

The letter MD means machine type—Multi-Disk Screw. Two former digits means the MD cylinder diameter, the last digit shows the number of the screw shafts, such as MD312,it means the MD cylinder diameter is 310mm, the number of the screw shafts is two.

② Sludge Treatment Capacity=DS Standard Capacity÷Sludge Concentration (DS stands for Dried Sludge, 0% moisture.

* Throughput of each model is based on sludge cake with 85% water content.

* There is no certain upper limitation on inlet sludge concentration, however, the target sludge must be flowable.

* Throughput of DAF Sludge is based on sludge containing much fat, oil, and grease such as meat processing applications etc.

* Throughput of Mixed Sludge (Primary Sludge and Waste Activated Sludge) and Aerobically Digested Sludge is based on sludge containing more than 30% fiber (200 mesh) against Total Solids.