-

111,South Yutian Road

Shanghai,China

-

Opening Time

Mon - Sat: 09.00 to 18.00

-

Mail Us

[email protected]

Introduction

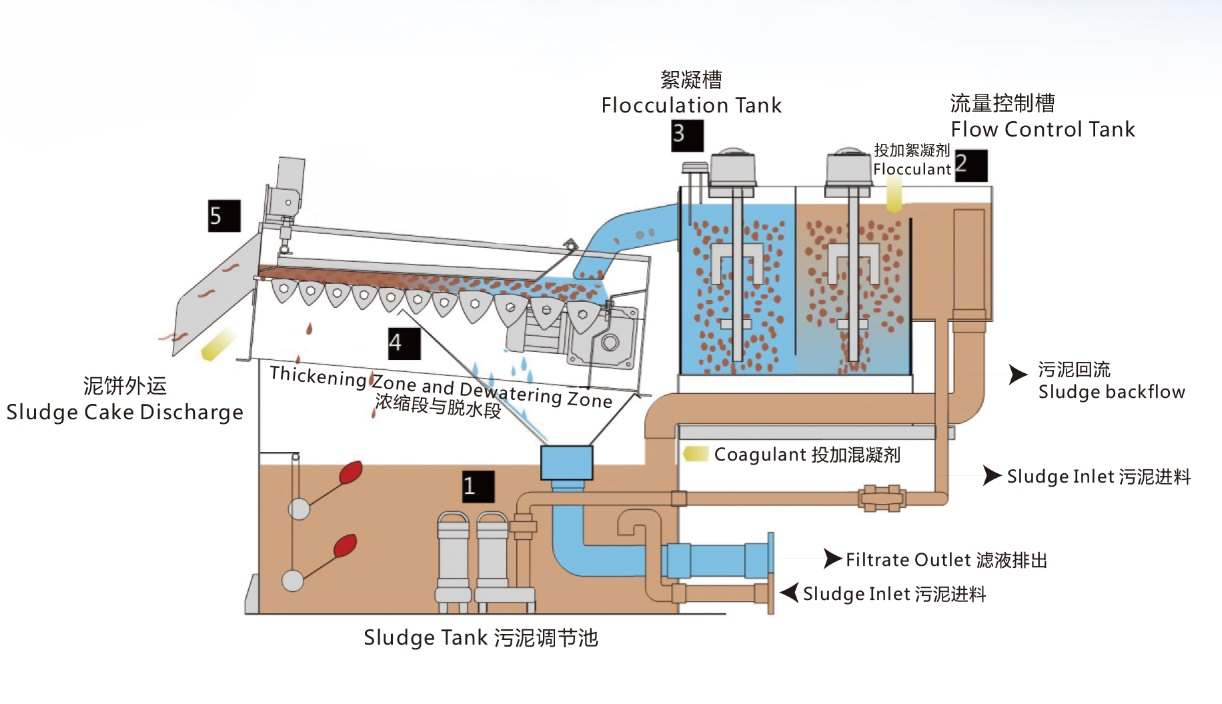

OP solid liquid separator adopt a unique separation technology. It’s brand new dewatering technology, which enables self-cleaning automatically for the filter gaps during sludge thickening and dewatering. Meanwhile this machine has stable and constant capacity without depending on high pressure backwash water to prevent clog. This self-cleaning system enables OP sludge dewatering press to be a good machine for oily and grease sludge.

The thickening and dewatering zone is composed of stainless steel screen bars and plate , they are interlaced with each other. The plates are all penetrate through the gaps between screen bars ( ≤ 1mm ).

During operation, the plates rotate slowly to transport sludge forward and the filtrate flows down through the gaps. During rotation, the plates are also cleaning the gaps between screen bars, so there is no chance for clogging.

Main Features:

1. No clogging

Continuous rotating the plates between the pressing plate, it causes high efficient separation from stock solution into liquid and solid at the same time, self-cleaning is occurred.

2. Stable treatment capacity

Continuous self-cleaning automatically for the filter gaps prevent the clogging, so it is guarantee the stable treatment capacity.

3. Large transport capacity

The plates runs smoothly in a wave-shape, which causes large transport capacity.

4. Operation is easy with high energy saving

Driving motor is high energy-saving, and it is very easy operation by using (ON-OFF) switch only.

5. Easy maintenance

Since structure is quite simple, maintenance is also easy.

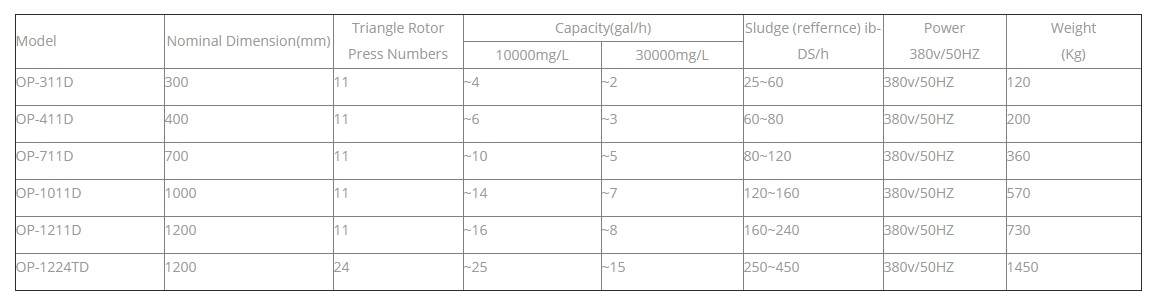

OP SOLID LIQUID SEPERATOR SPECIFICATION