We know that all vibration grinding can be used for grinding agents, glossers and other chemicals, or there will be grinding stones and product residues discharged after grinding, which will pollute the environment.

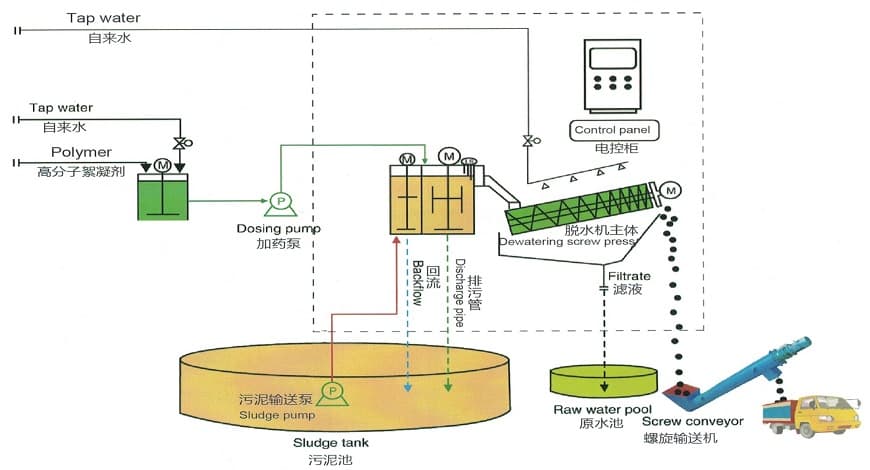

In the situation that everyone advocates low carbon environmental protection today, how to deal with these harmful substances produced by grinding industry is a new topic and challenge. A new water treatment loop machine supplied by our company can effectively solve this problem!

1.Technical parameters of CFWT series water treatment unit:

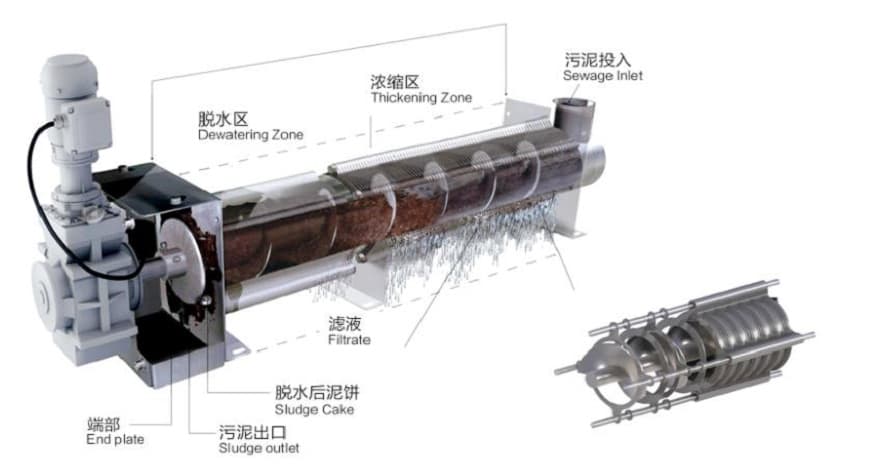

The centrifuge of grinding sewage treatment is to separate the sewage discharged after the vibration grinder works at high speed, so that the solid residue in the sewage is intercepted on the inner wall of the separator. It is a typical green product for environmental protection. It effectively prevents the random discharge of sewage, and effectively achieves the recycling of water resources. At the same time, the brightener added in the grinding process is retained, Cleaning agent and grinding agent have been recycled, which greatly reduces the production cost of enterprises, and is the best purification device for the wastewater treatment of grinding machine at home and abroad.

-

111,South Yutian Road

Shanghai,China

-

Opening Time

Mon - Sat: 09.00 to 18.00

-

Mail Us

[email protected]